Cases of contamination caused by a variant of brewer’s yeast known as diastaticus have become widespread, affecting an untold number of breweries—from Left Hand Brewing Co., based in Longmont, Colorado to Bell’s Brewery, based in Comstock, Michigan—and causing millions of dollars in product recalls in recent years. Contamination with this strain of yeast can cause beer to spontaneously referment, producing excess carbon dioxide. The resulting pressure can burst through glass, cans, or other packaging.

Beyond explosions, contamination with the strain can also produce off-flavors in the beer and cause alcohol to increase to noncompliant levels. This yeast variant is difficult to detect using traditional microbiological quality control practices. Because the cell structure of diastaticus is similar to that of more standard yeast strains, it’s not possible to identify it with a microscope. In addition, emerging research is leading brewers to believe that diastaticus is usually present in more than one strain.

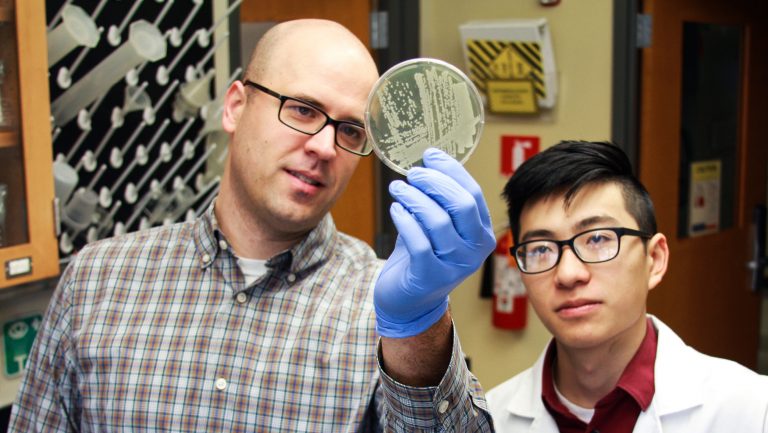

A new test now aims to diagnose the contaminant quickly and effectively. This year, Matthew Farber, the director of the Brewing Sciences Certificate Program at Philadelphia’s University of the Sciences, filed a patent for what appears to be a groundbreaking medium for growing and detecting diastaticus. Farber’s invention—the Farber Pham Diastaticus Medium (FPDM)—can detect low levels of several kinds of diastatic yeasts within one to two days of plating.

Don’t miss the latest drinks industry news and insights. Sign up for our award-winning newsletters and get insider intel, resources, and trends delivered to your inbox every week.

Farber has entered into an exclusive sales agreement with the New Jersey–based lab supplier Weber Scientific, which will sell 500 grams of dehydrated media for around $190, or approximately 36 cents per plate, starting December 17.

“We wanted to develop a better medium,” Farber says. On a commonly used medium, like the LCSM (Lin’s Cupric Sulfate Medium), results can be unreliable, he says. Other tests, like PCR (polymerase chain reaction), are rapid-detection kits that function like a pregnancy test—the appearance of two lines means positive for contamination. Farber says this kind of test can be confusing for brewers because they can’t see, and thus identify, the actual cells. And, he notes, PCR tests are more expensive.

“Diastaticus is not the sole cause of exploding cans, but it’s a big cause,” says Farber, who presented his research on the strain at the Master Brewers Association of the Americas summit this past summer. The strain—or strains—tends to “slip into normal brewery production as saison strains,” says Farber. Saison ale yeasts are diastatic, which gives the Western European style that dry effervescence that makes it so popular. But while traditional Belgian and French brewers typically age their beers in-house long enough to monitor for overpressurization, some U.S. craft brewers rush theirs out the door or don’t sanitize equipment well enough to avoid cross-contamination with other yeasts.

Until now, diagnosing diastaticus has been expensive. After a lab in Belgium identified the cause of the exploding of a bottle of Bell’s Brewery Winter White Ale in storage four years ago, Bell’s bought a Roche LightCycler, a piece of PCR testing equipment, to ensure that its products are free from contaminants. Luckily, the accident didn’t hurt anyone, but the machine, which can speedily determine results, within 2.5 hours, and at lower concentrations than traditional plating, set the brewery back $60,000. “We got it on sale,” jokes Lauren Torres, Bell’s lab manager.

Enhancing Beer Flavors with Cryogenic Technology

Craft brewers experiment with concentrated hops to boost bitterness in IPAs

Meanwhile, Left Hand Brewing Co. is embroiled in a lawsuit with its former yeast supplier following a recall that caused the brewery to have to destroy $2 million worth of product in 2016. The lawsuit alleges that the San Diego–based yeast supplier White Labs sold Left Hand a diastaticus-infected batch of yeast that it used to make its Milk Stout Nitro, Extrovert IPA, and Warrior Fresh Hop IPA.

(Both Left Hand and White Labs declined to comment for this story, though White Labs maintains that it puts its yeast through 61 test points and has never encountered unwanted diastaticus.)

Jamil Zainasheff, who coauthored Yeast: The Practical Guide to Beer Fermentation (Brewers Publications) with White Labs cofounder Chris White, says he’d be excited to try FPDM at his Heretic Brewing in Fairfield, California. “This would provide a reasonably cost-efficient way for breweries to test for diastaticus,” he says in an email. “Having a medium proven for all known strains is a real plus. This fits into most standard brewery lab operations, even at the small scale.”

Dispatch

Sign up for our award-winning newsletter

Don’t miss the latest drinks industry news and insights—delivered to your inbox every week.

Tara Nurin is the beer and spirits contributor to Forbes, the drinks columnist for New Jersey Monthly, a cohost of the What’s on Tap TV show, and a writer for publications like Food & Wine, Wine Enthusiast, Vice Munchies, and VinePair. She is a BJCP-certified judge, teaches a for-credit university beer class, and leads beer seminars for institutions like the Smithsonian. The Camden, New Jersey, homeowner has won two first-place awards from the North American Guild of Beer Writers, founded the state’s first beer education group for women, and volunteers as the archivist for the Pink Boots Society.