The Buffalo Trace Distillery in Frankfort, Kentucky, has installed digitally monitored temperature and humidity sensors in its newer warehouses, in the hopes of untangling some of the mysteries and minutiae of whiskey flavor development. Master Distiller Harlen Wheatley says, “We are searching for explanations on how and why a bourbon has a certain flavor. The environment, as we know, plays an important role.”

For years the distillery has been releasing its Experimental Collection whiskeys, in which various production parameters have been tweaked, including the ratio of grains distilled, the treatment of the wood used for barrels, and the size of the barrels the whiskey is aged in. Buffalo Trace also owns a small, experimental rickhouse known as Warehouse X (with its own blog), inside which several two-year-long and longer experiments are underway to study the effects of temperature, humidity, airflow, and natural light on whiskey as it ages in barrels held in a variety of controlled conditions in different chambers in the warehouse. (The first experiment conducted at Warehouse X, which concluded recently, showed that storing a barrel in a place with natural light doesn’t affect the color or the proof of the whiskey inside, as has often been thought to be the case for “honey barrels” placed next to windows.)

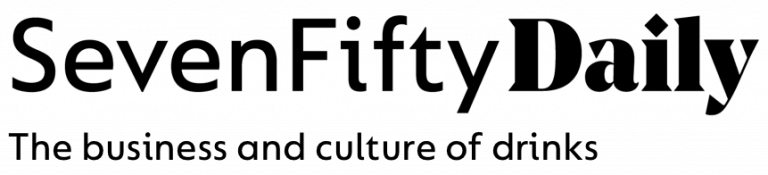

The new temperature and humidity sensors are not part of an ongoing experiment; they’re part of a long-term plan to collect data that can be used in the future. The sensors have been installed in two warehouses so far. Three more warehouses are currently under construction and will also have sensors installed. And older warehouses will be retrofitted with sensors, one per year, going forward. It’s safe to say that at this point the distillery is in the information-gathering stage.

Don’t miss the latest drinks industry news and insights. Sign up for our award-winning newsletters and get insider intel, resources, and trends delivered to your inbox every week.

Says Wheatley, “Once all the fingerprinting is complete, we will be able to target certain variables to help insure the best taste possible—temperature and humidity being just some of the contributors.”

The findings from Warehouse X and the Experimental Collection could have an effect on the distillery’s placement in the warehouse of whiskey designed for a specific flavor profile, but of course Buffalo Trace has been making whiskey for more than 200 years, and it’s fair to say they’ve already learned a thing or two about how to do that.

As whiskey ages in barrels, its flavor is affected by the wood, and its volume is reduced as water and alcohol evaporate over time at different rates, depending on the temperature and humidity conditions in the warehouse. The hotter upper floors of rickhouses are where producers tend to put the whiskey they want to be most affected by the wood in a relatively short time, whereas long-aged whiskeys tend to be stored on lower, cooler levels.

Of course, warehouses have had their temperature and humidity measurements taken in the past, but those thermometers weren’t digitally monitored. “We have monitored manually for decades,” says Wheatley, “however, we didn’t start really charting the history until a few years ago.”

Buffalo Trace has several different styles of rickhouse, with different microclimates, but even very similar warehouses have different aging conditions. The initial data coming from the distillery’s first two wired warehouses confirms this. The resulting line chart, taken over nine days in August from Warehouses T and U, displays the temperature at the first, third, and fifth floors in each. On the first and third floors, Warehouse U has lower temperatures than warehouse T, but on the fifth floor, a higher temperature. “The warehouses were built to be twins,” says Wheatley, “so they are very similar. However, since they are so large, the sheer location—east versus west, etc.—creates variations in the atmosphere.”

The new sensors may not upend the way whiskey is made in the near future, but they may be useful in identifying conditions that have caused certain barrels to behave differently from others. Should an anomalous barrel or set of barrels be discovered during inspection, Wheatley will be able to search through the data to discover what the previous years of aging were like in that particular part of the warehouse. Theoretically, he says, “if a bourbon has matured more than most, then we might be able to tie the temperature and humidity together to help explain some of the difference.”

Dispatch

Sign up for our award-winning newsletter

Don’t miss the latest drinks industry news and insights—delivered to your inbox every week.

Camper English is an international cocktails and spirits writer, speaker, and consultant, with a focus on the science of booze and big clear ice. His work has appeared in Popular Science, Cook’s Science, Whisky Advocate, Saveur, Details, the San Francisco Chronicle, and many other publications.