On site at Japan’s Fuji Gotemba distillery, which makes malt and grain whiskies at the foot of Mount Fuji, visitors will find a most important shrine—one dedicated to honoring yeast.

Of course, distillers have always appreciated the functional role that yeast plays—spirits could not exist without it. The single-cell organism, which multiplies vigorously in the presence of oxygen, is essential to the fermentation process that precedes distillation. When all the available oxygen is used up, yeast will convert sugar into alcohol. Fermentation is simply the process by which yeast converts sugar into alcohol and carbon dioxide.

But now an increasing number of distillers are emphasizing the role that yeast plays in building flavors and complexity too, though it may not—yet—get the same media attention as fancy barrel finishes or the use of heirloom grains. A handful of distillers are even starting to spotlight the humble microorganism in consumer-facing marketing initiatives, as Glenmorangie did earlier this year with its Allta bottling. The name, Scots Gaelic for “wild,” trumpets the fact that this experimental bottling was the first whisky the producer made with wild yeast.

“Yeast is probably your most important flavor component in whisky,” says Don Livermore, the master blender for Hiram Walker & Sons, a subsidiary of Pernod Ricard. He is well known for his work with Canadian whisky. “Most people don’t know that yeast makes alcohol,” he says. “And the majority of whisky consumers don’t care.” Some spirits producers are hoping that will change. After all, distillers certainly care.

Don’t miss the latest drinks industry news and insights. Sign up for our award-winning newsletters and get insider intel, resources, and trends delivered to your inbox every week.

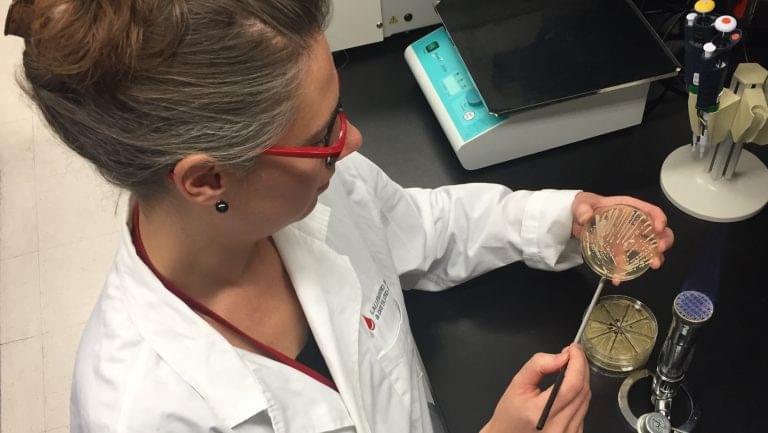

Some of the yeast strains used in distilling are handed down through generations; others are wild, their use intended to reflect local terroir; and many are purchased, after much deliberation about the foundation the yeast will help build for the finished spirit. Especially at larger distilleries, these strains are considered “proprietary,” with the mother, or starter, kept locked away in labs or refrigerated safes, often with a backup supply kept off-site—just in case. But whatever—and however—yeast is used, it’s clear that it’s a key to unlocking a spirit’s flavor.

Where Are Distillers Buying Yeast?

For most startup distilleries, the easiest way to acquire yeast is to purchase it. Lallemand Biofuels & Distilled Spirits, based in Montreal, is one of the largest producers of commercial yeast; it focuses primarily on baker’s yeast, selling about 90 percent of its output to bakeries, pizza makers, and the like. But Lallemand also sells yeast intended for fermenting wine, beer, and spirits. Currently, it produces 10 “distilling yeast” strains, with another being added this summer, specifically dedicated to malted grain fermentation.

For distillers, particularly the ever-growing ranks of craft distillers, Lallemand has focused its research on “flavor derived” yeasts, says Annick Mercier, the company’s technical sales manager for distilled spirits. These yeasts, dried and sold in vacuum-sealed packets, are targeted to produce specific types of spirits—and flavors. For those accustomed to thinking that the raw material of a spirit (like grains, fruits, and molasses) provides the flavor baseline, it’s eye-opening to realize that yeasts are involved in flavor as well: A more “neutral” yeast can be selected to make vodka, for example; for whiskey, a producer can select yeasts designed to produce a more (or less) aromatic spirit, or, according to Mercier, even a “complex whisky with a Scottish style.”

Some producers will test-drive many yeast strains to find the flavor profile they want. The flavors can range widely: Livermore has created a flavor wheel that illustrates what fermentation can bring to whiskey: fruity, floral, green grass, soapy, and sulfuric notes. All of these, he says, can be driven by yeast choice along with changes in temperature, pH levels, oxygen, and nutrient levels. In addition, Livermore says, fermentation can be soured intentionally with competing bacteria for additional flavors.

Much of the value of a commercial yeast strain is the consistency it permits, Mercier adds. “It’s about quality control, good yield, and not producing off-notes,” she says. While barrel-aging time is highly valued—according to some estimates, aging accounts for up to 60 percent of the flavor of a barreled spirit—it won’t correct a problem with the underlying distillate. “If you don’t have the precursors,” Mercier says, “the rest won’t be right.”

Beyond the Lab

Yet prefab yeast is just the starting point for most distilleries. Many supplement with yeast derived from other sources. For example, besides using commercial strains of yeast, Livermore is also the keeper of several historic strains. “I have strains of yeast from the original whisky barons of Canada,” he says, “from Henry Corby and J.P. Wiser and Hiram Walker, in a suspended state that I can get to grow.”

Similarly, Japanese whisky producer Nikka, headquartered in Tokyo, uses 10 different yeast strains culled from hundreds of potential options, says Tadashi Sakuma, the company’s chief blender. To find those strains, “we search many places,” he says—strains may be derived “from university strain libraries, from nature, from the mash of various facilities, and from mutation” and are then cultivated in-house.

For Japan in particular, yeast has provided a way to differentiate its native spirit from that of Scotland, which traditionally considered yeast as a functional, not a flavoring, tool; most Scotch distilleries used the same neutral strain for decades, Tadashi says. Scotch makers found other ways to flavor their whisky—smoking it with peat, for example, and exchanging whiskies among the numerous distilleries in the country to create what would become a culture of blended malts.

“In Japan, we do not have this culture of exchange nor the number of distilleries that would make that possible,” says Sakuma. “Therefore, we have been developing ways to produce various different types of whisky in-house, including the development of our own yeast strains.”

American spirits producers have also taken the reins in experimenting with yeast. Four Roses Distillery, in Lawrenceville, Kentucky, is among the most transparent in how it works with yeast, using five specific strains to make bourbon. Four Roses doesn’t do barrel finishes or other “innovations,” explains Brent Elliott, the company’s master distiller. “Any differences in the bourbon here come from variations in the mashbill—or from yeast.”

The distillery has been using the same yeast strains for the past 10 years, Elliott notes. Seagrams, which was Four Roses’ parent company starting in the 1940s (Seagrams was dissolved in 2000, and Four Roses has been owned by Japan’s Kirin Brewery Company since 2002), isolated the originals, Elliott says, starting with about 350 strains in its library. The final strains were selected based on the flavors they provide—two styles of fruity (one delicate, one bolder), as well as spicy, floral, and herbal. These yeast varieties, he says, create further reactions during fermentation that can add richness and complexity.

So to say that Four Roses appreciates yeast is a bit of an understatement. “That’s our uniqueness; we tout it,” Elliott says. “We feel that [yeasts are] at the front end in creating those unique flavors at the very beginning of the fermentation.”

Not Just Whiskey

While whiskey makers are certainly the most vocal about the effects of yeast selection right now, other spirits categories are starting to highlight yeast as a differentiator. For example, the tequila maker Herradura, headquartered in Jalisco, Mexico, famously claims to use 100 percent wild yeast to spontaneously ferment its agave mash, with hundreds of yeast strains—which may be typical for artisanal mezcals and tequilas, but is a far cry from the typical practice of the large producers that have a foothold in the U.S. market.

While it’s not standard practice across the tequila industry, a small number of producers use wine yeast (rather than brewer’s or distiller’s yeast) to ferment their agave. For example, PaQuí Tequila, whose distillery is located in Tequila, Mexico, introduces wine yeast to help highlight “the best of the fruit and florals that are in the agave before we start [with distillation],” says John Chappell, PaQuí’s founder and CEO, who is based in New York City. In comparison, airborne yeasts can add “sour, funky” notes that can interfere with tequila’s more delicate aromas and flavor compounds, he says. Similarly, the tequila brand Volcán de Mi Tierra uses Champagne yeast for a “more expressive” spirit, according to the producer.

Rum, another category that often often places a premium on local character, also sometimes showcases the effect of yeast. While it’s by no means usual in this highly fragmented category, some types—including clairin, rhum agricole, and cachaça—emphasize natural yeasts and fermentation methods. Interestingly, Hard Truth Distilling, a rum maker based in Nashville, Indiana, purchased a yeast strain isolated from rum distilleries in the Caribbean to create “fruity, tropical notes” in its rum. The project raises a question about the geography of yeast: Is it possible to import terroir for a spirit?

Combining Influences, Pushing Borders

While it’s tempting to draw a dividing line between spirits made from cultivated yeasts (or “introduced” yeasts, in industry parlance) and those made from “wild” yeasts imparting the essence of local terroir, the truth is that many distilleries use some combination of the two.

Four Roses, for example, may rely on its five well-cultivated strains, but like many distilleries, it also uses open fermentation tanks, so the bubbling liquid is exposed to the air and whatever may be floating about. “We know there’s wild yeast getting in there,” Elliott says. “The influence—I don’t know. But I wouldn’t dismiss that as contributing to the final flavor of my product.”

In fact, the potential impact of that wild yeast prevented Four Roses from moving to another location—it chose to expand the facility on its existing site instead. “We didn’t want to risk the flavor profile by taking this off-site,” Elliott says. “We couldn’t even entertain the idea [of moving], because we’re too respectful of the possibility that terroir is influencing the product more than we can quantify.”

Other producers actively embrace the idea of “wild” and create the pét-nat equivalent of the spirits world. Among American craft producers, Denver’s Leopold Brothers is at the forefront of this approach, growing flowering plants along the distillery walls with the intent that open windows will encourage local yeasts to propagate during whiskey ferments in addition to cultivated yeast (the head distiller, Todd Leopold, says he typically uses three yeasts in each of his ferments).

After a traditional 72-hour fermentation, Leopold explains, his approach is to allow an additional 48 hours to let the wild yeast “go to work,” a method he likens to high-ester rum production (a super-funky style that can rely on extra microbial fermentation). “Our intent,” he says, “is to add more depth and complexity to the finished whiskey.”

The method has also added an unexpected “house note” to the whiskey. In contrast to Four Roses, which chose not to move to avoid interfering with its whiskey’s flavor profile, Leopold found that when his distillery moved into a new location five years ago, it indeed changed the spirits he made—but in a way that he loved, layering on a delicious orange marmalade note: “It’s in everything we’re making.” And Leopold firmly attributes that house note to the local microbes.

“It’s showing up spontaneously,” he says, “and we can’t make it anywhere else.” This kind of elusive reaction explains why distillers go to such lengths to find and nurture the “right” yeasts—even to the point of building shrines to honor them.

Dispatch

Sign up for our award-winning newsletter

Don’t miss the latest drinks industry news and insights—delivered to your inbox every week.

Kara Newman reviews spirits for Wine Enthusiast magazine and is the author of Shake. Stir. Sip., Nightcap, and Cocktails with a Twist (Chronicle Books).